Notes on the Koppermaandag print for Drukwerk in de Marge

Raise your hand at a meeting and voila, a project: 650 ‘Copper monday’ prints please, thank you.

Well, lets get to work then.

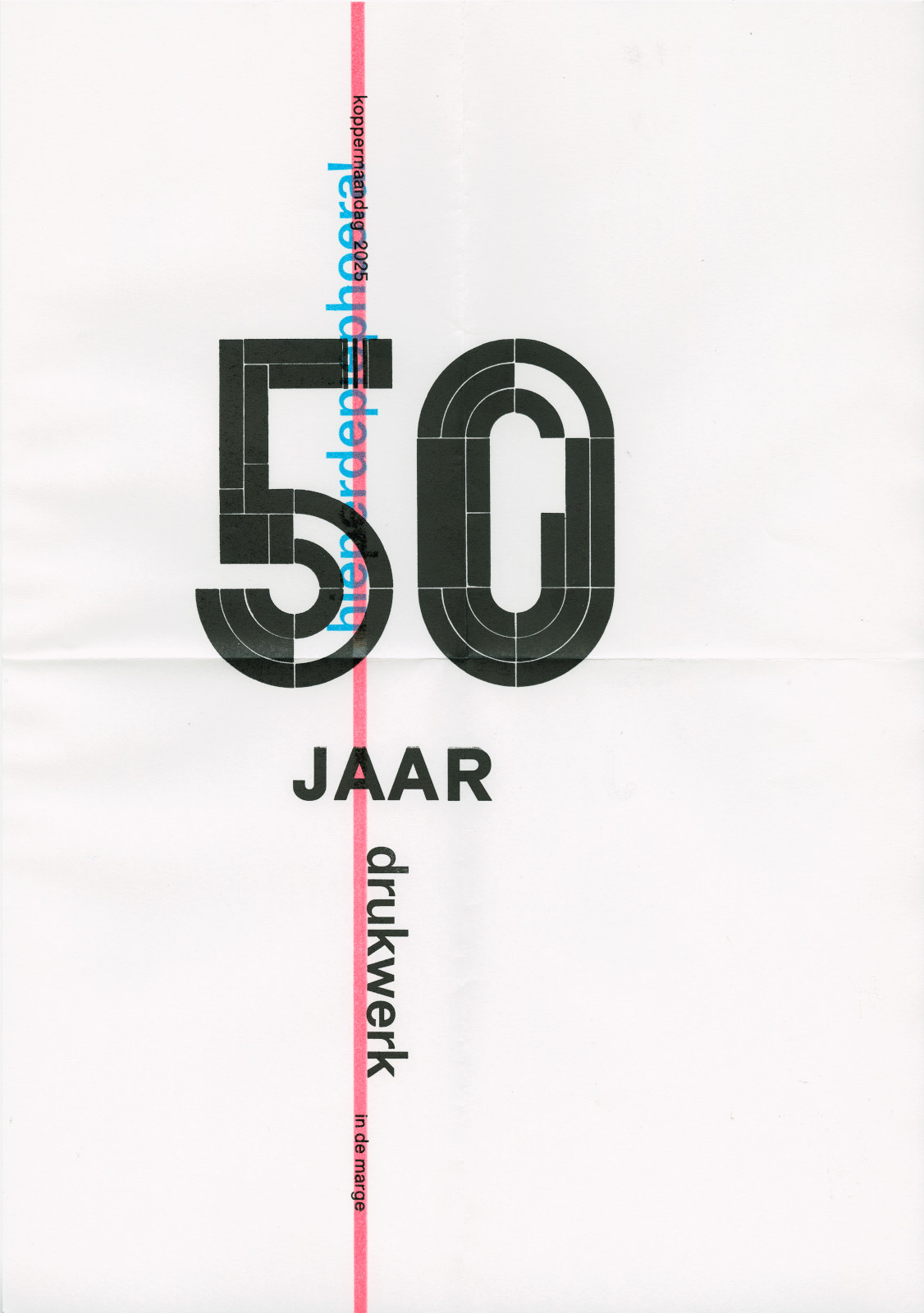

Topic for the design had to be the foundations fiftieth birthday of course. Stichting Drukwerk in de Marge translates as Foundation Printing in the Margin. For the design I took both ’the margin’ and ‘in’ literally, visually. Which gave me that vertical line, in the same red-ish pink that you still find in your exercise book. That line then provided the base for positioning the other bits of text, where ‘in the margin’ had to end up exactly in that margin. Of course it wouldn’t be a print made at our studio without a bit of LEGO Letterpress using the Hilversum Method. The number 50 uses customised versions of the numerals in the QUNZ type family designed by Martijn van der Blom.

All of that made this a technical exercise in exact positioning. So that line exactly vertical. So that the blue text would print exactly right over the red line (which I managed to achieve in one go). So that the smallest text would really be inside the margin (which required adjustments when the forme was alreay in the press), etcetera.

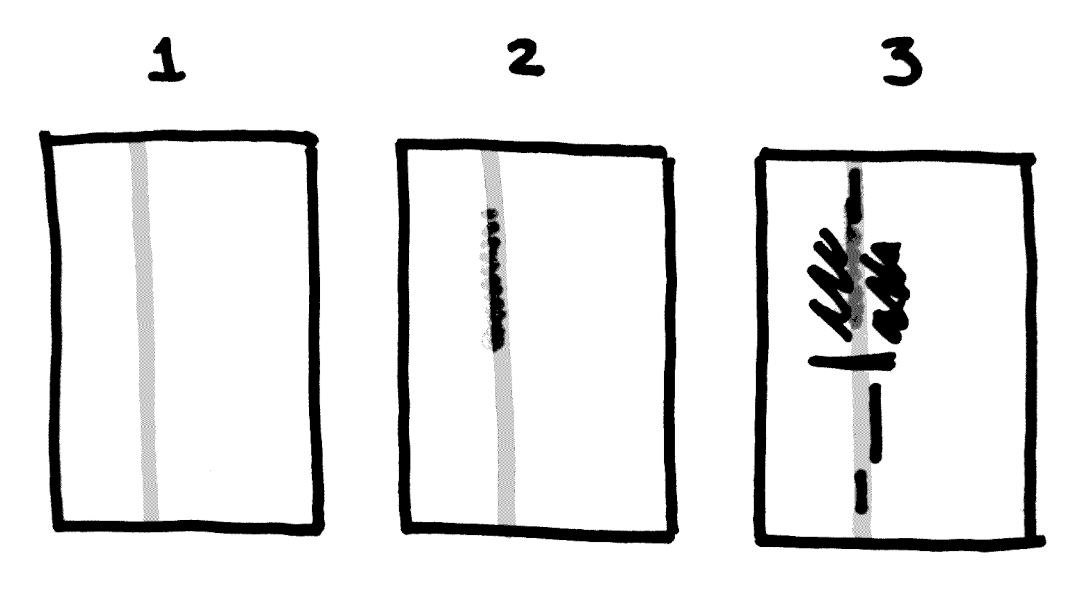

The first print run was for just that red line. Width 1 cicero, exactly 25 cicero from the left side of the paper. Even after more than six hundred prints that line was still in that same position. The combination of a thousand kilos worth of printing press and the razor-sharp precision you can achieve with it is truly fascinating.

The second print run added the blue text. I was chuffed when it immediately showed up in the right place because I had correctly calculated my points and ciceros. The third and final print run in black used the most complex forme. Combining small, subtle type with the relatively large solid areas of the LEGO numerals and getting both to print nicely was challenging.

And we changed presses for this third run, moving from the manually operated Vandercook to the electrically driven Grafix. A smaller and faster press which perhaps was a bit more suited for this challenging forme. Not only getting everything to print evenly was challenging. Calculations made during composition turned out to be miscalculations this time. A few points of line height had to be shuffled around to get things aligned nicely. Eventually we sorted that out as well. My thanks to Thomas and Martijn for their help with this part, and producing all those copies.

- The paper used is 90 gsm A3 biotop. Maybe this light weight can help save on postage :)

- Getting 700 sheets out of the drying rack and stacking them is work, too. Nothing is ‘quickly’ with these numbers.

- You need quite a bit of drying rack anyway…

- Speed of manual printing was around three sheets per minute, around 180 per hour. On the semi-automatic press that was around 250 sheets per hour.

- You get the sheet including ‘gripper white’ and all. That too is (in the) margin.

Congratulations to the board members of Stichting Drukwerk in de Marge, to all contributors and printers in the low countries. Here’s to the next fifty years!

The original Dutch version of this article first appeared in the Drukwerk in de Marge Newsletter nr. 191